Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

steps and process of unidirectional carbon fiber fabric for structural strengthening

In the process of structural strengthening of a building, it is first necessary to fully understand the structure of the building. Then use this as a basis for appraisal of building usage, and then formulate corresponding structural strengthening schemes based on the appraisal results. Next, carry out the structural strengthening design of the system and formulate the corresponding construction plan. Then the actual construction is carried out according to the content specified in the construction plan, and the unified acceptance is carried out after the completion of the project.

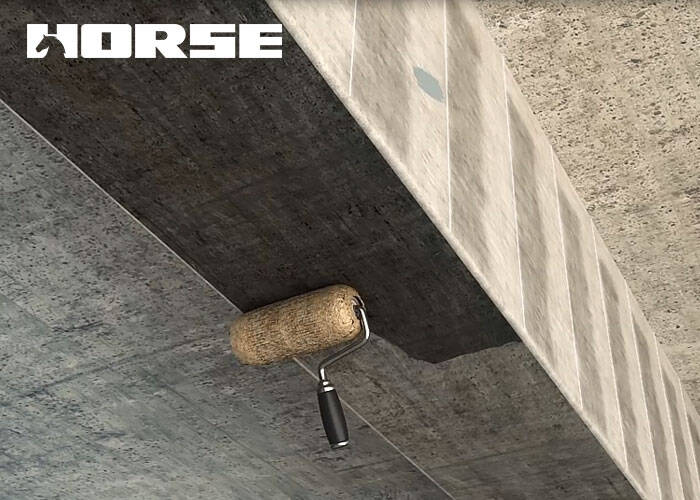

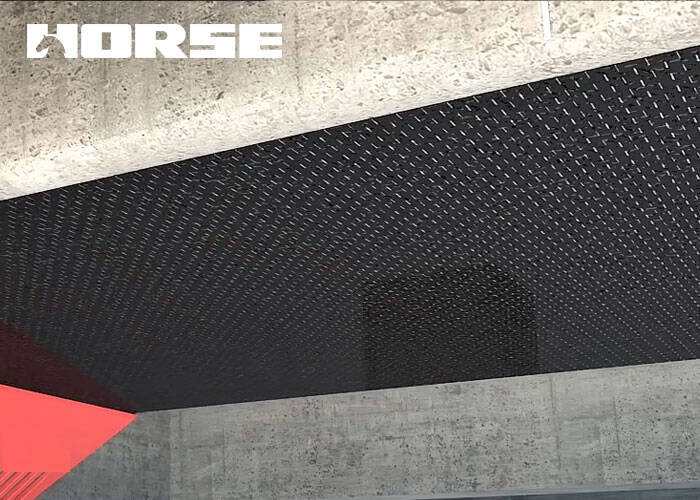

When using unidirectional carbon fiber fabric for structural strengthening, it is first necessary to perform simple processing on the surface of the reinforced structural member. Then mix the adhesive according to actual needs, and then apply a layer of primer evenly on the surface of the part to be reinforced. After ensuring that the surface is smooth, apply a layer of adhesive, use the adhesive to lay a layer of unidirectional carbon fiber fabric, and finally lay a protective layer.

In order to ensure the overall quality of structural strengthening, we should ensure that prior to structural strengthening, focus on cleaning the surface. The loose attachments on the surface of the reinforced component are completely removed, leaving the stable part of the concrete structure layer, and the incomplete part is repaired. If it is found that there are cracks in the reinforced component, it should be properly filled or completely sealed according to the size of the crack. After the surface of the concrete is polished, the floating dust on the surface should be removed in time. The corner paste of the concrete structure should also be polished properly until the corners are rounded. The prepared adhesive should be stored reasonably to avoid direct sunlight. At the same time, during the specific construction, it should be ensured that the use of the adhesive will not cause interference and influence on the surrounding conditions. In addition, when the carbon fiber is attached, the ratio of the adhesive should be strictly controlled. The prepared adhesive should be used up at one time to avoid adverse situations caused by the change of adhesive properties during secondary use.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.