Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

New structural srengthening technology-carbon fiber structural srengthening

Structural fiber reinforced polymer(FRP) strengthening is a method of using high-strength fiber materials such as carbon fiber and glass fiber to reinforce the structure. It has the advantages of good durability, simple construction, no increase in section, no increase in load, and beautiful appearance. It has been successfully applied to the seismic, bending and shear strengthening of various structures.

Carbon fiber for seismic strengthening

Wrap the reinforced concrete column with carbon fiber material so that the fiber direction is perpendicular to the axis of the column, which can effectively improve the ductility and bearing capacity of the column and increase its seismic energy dissipation capacity. In addition, as the main lateral force-resistant member, the shear wall is nothing more than flexural ductility failure (medium-high shear wall) or shear brittle failure (low shear wall). Carbon fiber is used to strengthen the shear wall, as long as the method is appropriate, it can also significantly improve its ductility and bearing capacity. Therefore, the seismic strengthening of reinforced concrete structures is an effective field of application of carbon fiber materials. However, it should be pointed out that when carbon fiber is used to reinforce columns or shear walls, because carbon fiber itself is a pre-flexible material, it is bonded to the reinforced structure through structural glue, which requires the reinforced concrete to meet certain strength requirements. It is possible to exert the reinforcing effect of carbon fiber. The following takes actual engineering as an example to illustrate the method of reinforcing reinforced concrete columns with carbon fiber and improving seismic performance.

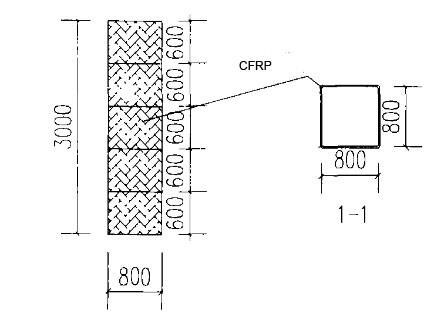

For a multi-layer reinforced concrete frame structure, it was found during construction acceptance that the concrete strength of 9 frame columns could not meet the design requirements, resulting in excessive axial compression ratio and unable to meet the ductility requirements required by the axial compression ratio limit. In this regard, it was decided to use carbon fiber cloth to wrap the column strengthening scheme. On the one hand, the reason is that the wrapping of carbon fiber has a hoop effect on the column concrete, which can improve the axial compressive strength of the concrete to a certain extent. On the other hand, the lateral restraint effect of carbon fiber on the column can also significantly improve the ductility of the column under horizontal loads. Through the calculation of bearing capacity and ductility, the solution of 3 layers of carbon fiber cloth wrapped along the entire column height range is adopted for the 3 columns with lower strength, and the solution of 2 layers of carbon fiber cloth wrapped along the entire column height range is adopted for the other 6 columns. . The strengthening scheme is shown in Figure 1.

Carbon fiber used for flexural strengthening of floor slab

Because of its high tensile strength, carbon fiber materials can be used for flexural strengthening of concrete components. When carbon fiber is used for flexural strengthening, the fiber sticking direction should be parallel to the main force direction of the member. In addition, when calculating the bending bearing capacity of the reinforced structure, the reduction of the ultimate strength of carbon fiber should also be considered. The following examples illustrate the carbon fiber bending strengthening method.

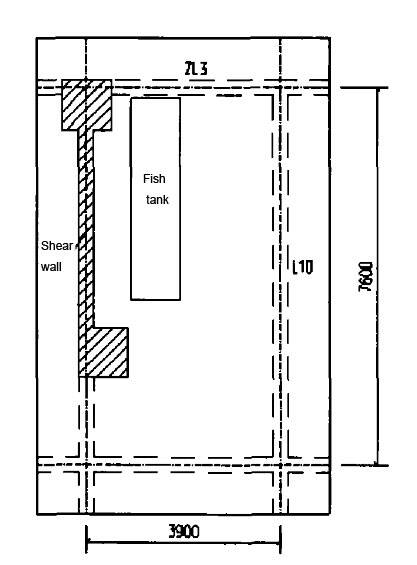

There is a cast-in-place reinforced concrete frame-shear wall structure. The original floor slab is 120m thick. Now it is planned to add a large fish tank, weighing 3.6t, and the size of the fish tank base is 4.6*1.2m (Figure 2). Due to the large new load, the original structure must be reinforced. For the positive bending moment area of the floor slab, the method of pasting carbon fiber cloth can be used for strengthening. Studies have shown that, on the one hand, when the amount of reinforced carbon fiber cloth is large, the strength that can be achieved in the ultimate state of the floor bearing capacity is low, and its strength cannot be fully utilized. On the other hand, if the amount of carbon fiber material is reduced, it can reach a higher stress in the ultimate state of bearing capacity, but because the elastic modulus of carbon fiber is close to that of steel, the board may be damaged due to excessive deflection under the limit state of normal use.

Applicability of carbon fiber strengthening method

As mentioned above, carbon fiber can be successfully used for seismic, shear and flexural strengthening of concrete structures. However, it should be pointed out that due to the inherent stress characteristics of carbon fiber reinforced structures, many concrete structural problems are not suitable for carbon fiber strengthening, so it is necessary to analyze its applicability.

1. Stiffness problem

When the concrete building or roof structure is insufficiently rigid, resulting in excessive deformation and serious cracking, which affects the use, it is not suitable to use the method of sticking carbon fiber cloth to reinforce. For beams, plates and other transversely stressed members, when carbon fiber is used for strengthening, in the limit state of normal use, the effect of carbon fiber on the structural rigidity is less than 10%, or basically no improvement.

2. The scope of application of carbon fiber bending strengthening

When the concrete structure is reinforced with carbon fiber cloth due to insufficient flexural bearing capacity, the failure mode of the reinforced structure depends on the strengthening of the original structure on the one hand, and the amount of carbon fiber on the other hand.

3. Torsion problem

Regarding the torsion-resistant strengthening of concrete structures with carbon fiber materials, few studies have been conducted at home and abroad. From the perspective of the torsion failure mechanism of the concrete structure, whether the fiber direction of the carbon fiber is perpendicular to the axis or parallel to the axis, the development of torsion diagonal cracks can be restrained and a certain strengthening effect can be achieved.

In summary, the carbon fiber strengthening method can be used for bending, shearing and seismic strengthening of concrete structures. However, each has its scope of application. When calculating the bearing capacity, the reduction of carbon fiber strength should be considered based on the test results. The carbon fiber strengthening method is not suitable for the strengthening of concrete structures in the limit state of normal use due to insufficient rigidity, excessive deformation. When used for torsion strengthening, although it can play a certain role, it is not economical.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.