Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

bridge reinforcing strengthening with Horse carbon fiber wrap

Introduction to the project

The Yangshu Bridge is located in the Dalian Economic and Technological Development Zone. The design structure is a 3-13m reinforced concrete simply supported structure. The original bridge main girder is marked with C30. The bridge deck layout is net -11+2x0.5 meters, the lower structure is U-shaped abutment, gravity bridge pier, the foundation is expanded foundation, and the original bridge is equipped with C40 expansion joints at both ends of the bridge head.

After investigation and calculation, the situation is as follows

a. Based on experience, the lower structure meets the load requirements (car -20 to highway 1 load), and no reinforcement is required.

b. Bridge deck system. Longitudinal cracks appear in the bridge deck's twisted joints, and the cracks are wide, which poses safety hazards and affects vehicle traffic. Two of the damages were serious. The width of the gap was 10cm (beam flange broken). The expansion joint was seriously damaged. The two sides of the joint were broken, and the rubber strip was exposed and broken.

c. Main beam. There are different degrees of cracks on the bottom surface of the main beam span, and there are many individual cracks. The crack spacing ranges from 150-400mm, and the width is 0.1-0.2mm (0.2mm is only one place).

Horse is a manufacturer of structural reinforcement materials, so today we only discuss carbon fiber wrap reinforcement. Carbon fiber reinforcement repairs the disease of the main girder of the poplar bridge.

Bridge reinforcement plan

Since the bridge is located in a busy section of the development zone, it is required that the time of traffic closure should be as short as possible, and the load on the old bridge should not be increased as much as possible during reinforcement. For this reason, a carbon fiber wrap reinforcement scheme was selected for this project.

Features of carbon fiber wrap reinforcement scheme

Do not increase the dead load and section size. The weight of the carbon fiber wrap is only 200-300g/m2, the design thickness is 0.111-0.333mm, and the weight of the epoxy resin series bonding material is also very light. The impact on the weight of the entire structure and the clearance under the bridge is negligible. At the same time, the carbon fiber wrap can be pasted in multiple layers. According to the reinforcement requirements, the carbon fiber wrap can be pasted in one place to fully meet the reinforcement requirements. This advantage is unmatched by traditional reinforcement methods. The use of carbon fiber wrap reinforcement in this project has almost no effect on the geometric dimensions of the original section, maintaining the force system of the original rigid frame arch. Compared with increasing the arch rib section, the original arch axis of the rigid frame arch rib is changed, which is not conducive to the force of the arch rib.

The construction is simple and the construction period is short. The carbon fiber wrap is soft, has no shape requirements for the reinforcement, does not require prefabricated materials, large construction machinery and on-site fixed facilities, and has a short construction period.

Carbon fiber wrap is used for reinforcement and no new damage to the original structure. The reinforcement of carbon fiber wrap is made of epoxy resin series bonding materials. There is no need to install wrong fixation and excavate concrete, so it will not cause new damage to the damaged structure, and it can also avoid the original structure during drilling. There are conflicts between steel bars and prestressing elements, causing new problems.

Can effectively close the cracks in concrete. The carbon fiber wrap (sheet) is pasted on the surface of the concrete, which not only closes the cracks in the concrete, but also restricts the generation and propagation of cracks in the concrete structure due to its high-strength and high-modulus characteristics and changes the shape of the cracks. The wide and deep cracks become scattered fine cracks, thereby improving the overall rigidity of the concrete components.

Carbon fiber wrap has excellent chemical resistance. Carbon fiber wrap is a composite material, almost non-corrosive and magnetic, and has good heat resistance. Not only can it withstand the alkali corrosion of cement, but also has a long life when used in corrosive environments such as frequent corrosion by salt. Therefore, the carbon fiber wrap reinforcement method shows its superiority compared with other methods in adverse environments.

Does not affect the appearance of the structure. The thickness of the carbon fiber wrap is very thin. After being pasted and cured, the surface can be painted with a layer of paint consistent with the appearance of the original structure without affecting the appearance of the structure.

Carbon fiber wrap reinforcement

There are 30 main beams in the whole bridge, and the middle and side beams are pasted with the same amount of carbon fiber. Before the carbon fiber is pasted, the beam body must be treated, degraded concrete and other diseases treated and cleaned, and the corners must be chamfered.

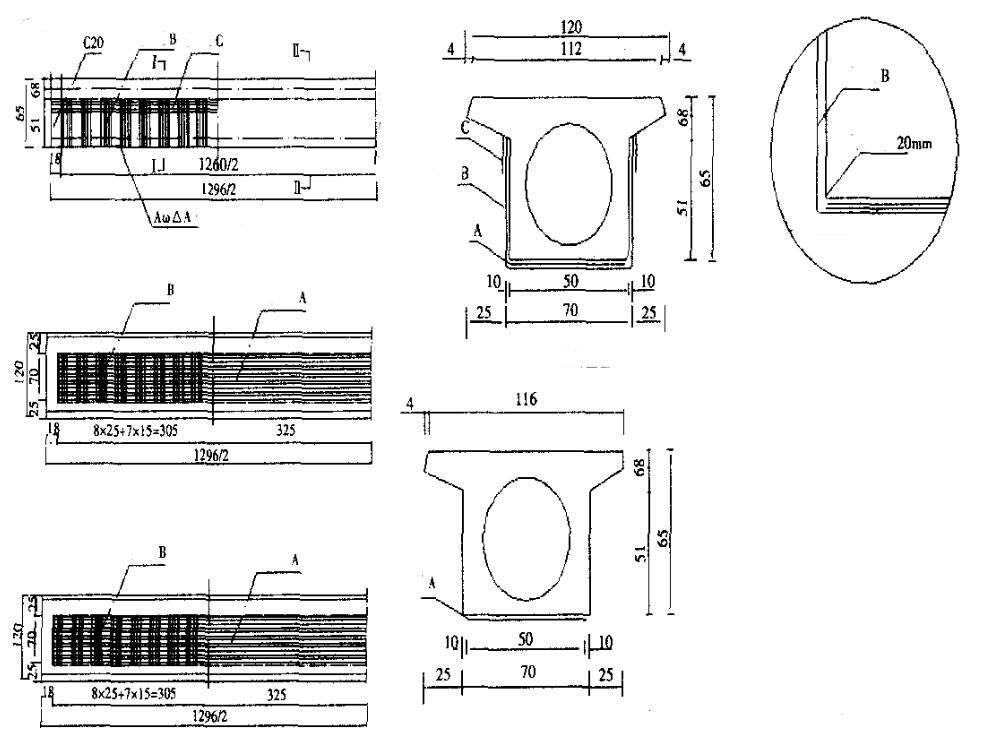

During the construction process of carbon fiber, it is necessary to pay attention to the sticking direction of the main carbon fiber reinforcement and the direction of the layer shear reinforcement fiber and the axial direction of the main beam. The fiber direction of the bending reinforcement is the same as the axial direction of the main beam. The average thickness of the bonding resin shall not be less than 2mm. When carbon fibers need to be overlapped along the longitudinal direction of the main beam, the overlap length should not be less than 10cm and the overlap position of each fiber should be staggered. The specific scheme is shown in the figure below:

The main bridge reinforcement materials

Carbon fiber wrap (CFRP). The reinforcement of this project uses Horse's HM-20 carbon fiber wrap to reinforce the bridge arch.

Bonding material: HM-180C3P carbon fiber adhesive

Project summary

The load test verifies that the poplar bridge is basically restored to its original load-bearing level after being reinforced with carbon fiber wrap.

The carbon fiber wrap reinforced section structure bridge is a new technology. The carbon fiber sheet is light, no heavy equipment is needed for on-site pasting, and the facility is simple and convenient for the high-altitude function under the bridge. It can be popularized and applied on highway bridges.

At present, the reinforcement methods of pasting carbon fiber sheets are often supplemented by methods such as crack grouting and crack sealing.

Carbon fiber reinforcement is mainly to share the stress of the steel bars, that is, to increase the tensile strength of structural members. Then, after the use of carbon fiber reinforcement, whether there will be a negative impact similar to the super-reinforced damage of reinforced concrete structural members remains to be explored.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.