Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Equivalent Conversion Method for Different GSM Unidirectional Carbon Fiber Fabrics (ACI/ASTM Compliant)

In structural reinforcement projects, unidirectional carbon fiber fabrics of different basis weights cannot be directly interchanged physically. They must be converted and selected based on the principle of equivalent tensile bearing capacity to ensure that the mechanical properties of the reinforced component meet design requirements (complying with ACI 440.2R and ASTM D7565 standards). The following are the specific conversion logic, formulas, and practical examples:

Core Conversion Principles

The reinforcement effect of carbon fiber cloth is determined by the effective tensile area × tensile strength, i.e., equivalent tensile bearing capacity. The conversion is based on the following premises:

The tensile strength grade of carbon fiber cloths of different weights is consistent (e.g., all are Grade I, tensile strength ≥ 3600 MPa);

The number of bonding layers can be adjusted, and the surface bonding space constraints of the component are met (to avoid excessive layers leading to bonding failure).

Conversion Formula

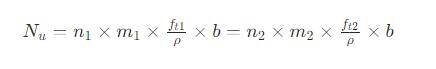

Derived from the equivalent tensile bearing capacity formula:

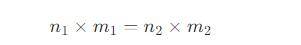

When ft1 = ft2 (same strength grade), and fiber density ρ and bonding width b remain unchanged, the formula simplifies to:

n1/n2,

Number of bonded layers of two types of carbon fiber fabrics

m1/m2

Grammage (GSM, g/m²) of two types of carbon fiber fabrics

t1/t2

Tensile strength (MPa) of two types of carbon fiber fabrics

p

Carbon fiber density

b

Bonding width of carbon fiber fabric (m)

Practical Conversion Case

Taking the common Grade I carbon fiber fabrics of 300 g/m² and 600 g/m² as an example:

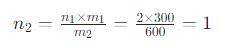

1. Known Conditions: The original design adopts 2 layers of 300 g/m² carbon fiber fabric to strengthen the beam; only 600 g/m² fabric is available on site.

Calculation by Substituting into the Formula:

1 layer of 600 g/m² carbon fiber fabric can be used to replace 2 layers of 300 g/m², achieving fully equivalent tensile bearing capacity.

What if the strength grades are inconsistent?

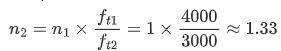

If the tensile strengths of the two carbon fiber fabrics differ (e.g., Grade I vs. Grade II), the tensile strength coefficient must be calculated first to adjust the number of layers.

For example:

To replace 300 g/m² Grade II fabric (ft=3000MPa) with 300 g/m² Grade I fabric ((ft=4000MPa), the required number of layers is:

so you need bonding 2 layers

Precautions

Maximum number of layers: The recommended number of unidirectional carbon fiber cloth layers should not exceed 4 (too many layers can easily lead to blistering and peeling).

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.