Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How Should Load-bearing Walls Be Strengthened?

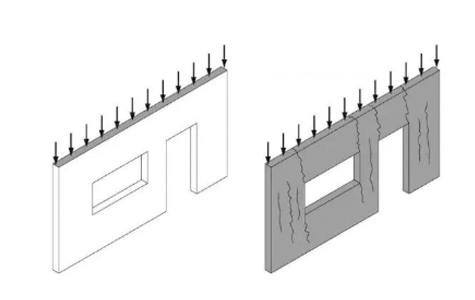

The load-bearing wall refers to the wall that supports the weight of the upper floor. It is a black wall on the engineering drawing. If it is knocked down, it will destroy the entire building structure and affect the earthquake resistance. In the actual renovation project, some owners choose to knock out or destroy the load-bearing wall in order to open up the space and design a beautiful design, which leads to a series of safety problems. Therefore, in order to protect the safety of the building structure, not only can we not destroy the load-bearing wall, but also strengthen it if necessary.

There are five main methods for strengthening load-bearing walls:

1. Wire winding reinforcement method

The wire winding method is one of the methods for strengthening the load-bearing wall. This strengthening method is mainly aimed at the load-bearing wall under the condition that the bearing capacity of the inclined section of the concrete structural member is insufficient, or the lateral restraint force of the compression member is applied. If you make a door opening, you can choose to wire it for reinforcement.

2. Replacement concrete reinforcement method

The replacement concrete reinforcement method is usually used for the reinforcement of concrete load-bearing members such as beams and columns with low concrete strength in the compression zone or serious defects. The replacement depth of concrete should not be less than 40mm; when the beams and columns are artificially poured, it should not be less than 60mm, and when the spraying method is used, it should not be less than 50mm. The replacement length shall be determined according to the test results and calculation results of the concrete strength, but for the case of non-full-length replacement, the two ends shall respectively extend a length of not less than 100mm.

3. Bondng carbon fiber reinforcement method

Use the method of pasting carbon fiber cloth or mesh cloth to enhance the bearing capacity of the load-bearing wall. This method not only has similar advantages to steel mesh, but also has the advantages of good corrosion resistance, moisture resistance, long service life, low maintenance cost and almost no increase in the weight of the structure. It is suitable for concrete structural members and general structures of various mechanical properties.

4. Enlarged section reinforcement method

The method of strengthening the load-bearing wall by increasing the section is usually suitable for concrete reinforcement of beams, slabs, columns, walls and general structures, and has the advantages of convenient and simple construction and strong adaptability. However, if this method is constructed on site, the wet operation time will be relatively long, and the net space area of the reinforced building will be reduced to a certain extent, which may have a little impact on life. However, it should be noted that this reinforcement method should not be used in unprotected high temperature places above 600 °C.

5. Bonding steel plate reinforcement method

The reinforcement method of pasting steel plates is often used for the reinforcement of bending or tension members subjected to static force in a normal humidity environment. The construction efficiency is fast, and there is no wet operation on site, which has less impact on life. For example, for door or window openings with an area of more than 0.3 square meters in load-bearing walls or shear walls, it is better to use bonded steel reinforcement. Before construction, remove the plastering layer on the surface of the base and expose the concrete surface. The angle grinder grinds the steel concrete to be bonded, removes the dirt on the surface of the concrete, and exposes the stones. If you encounter uneven or defective parts, use structural glue or cement mortar to smooth them, and then prepare for the next process.

Draw the sticking steel position line on the surface of the concrete according to the design drawings, and then use an electric hammer to hit the bolt hole for the anchoring steel plate. The dust in the bolt hole should be removed, and the expansion bolt should be fixed. For steel plates below 6mm, use a shearing machine to cut. Finally, according to the position of the anchoring expansion bolt, use a bench drill to drill holes on the steel plate, and the hole diameter is required to be larger than 2mm of the expansion bolt, and fix the welding and glue injection.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete