Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Application of Prestressed Carbon Fiber Strip in Bridge Reinforcement

At this stage, many old bridges have suffered bridge diseases, which have seriously affected the normal performance of the bridges. Therefore, it is urgent to develop effective bridge strengthening technologies. Prestressed carbon fiber strip reinforcement technology is a new type of reinforcement technology. It relies on the high tensile strength of carbon fiber strip to form a carbon fiber strip prestressed system, which can increase cracking load and yield load, inhibit component deformation and crack propagation, and play a role in strengthening the bridge.

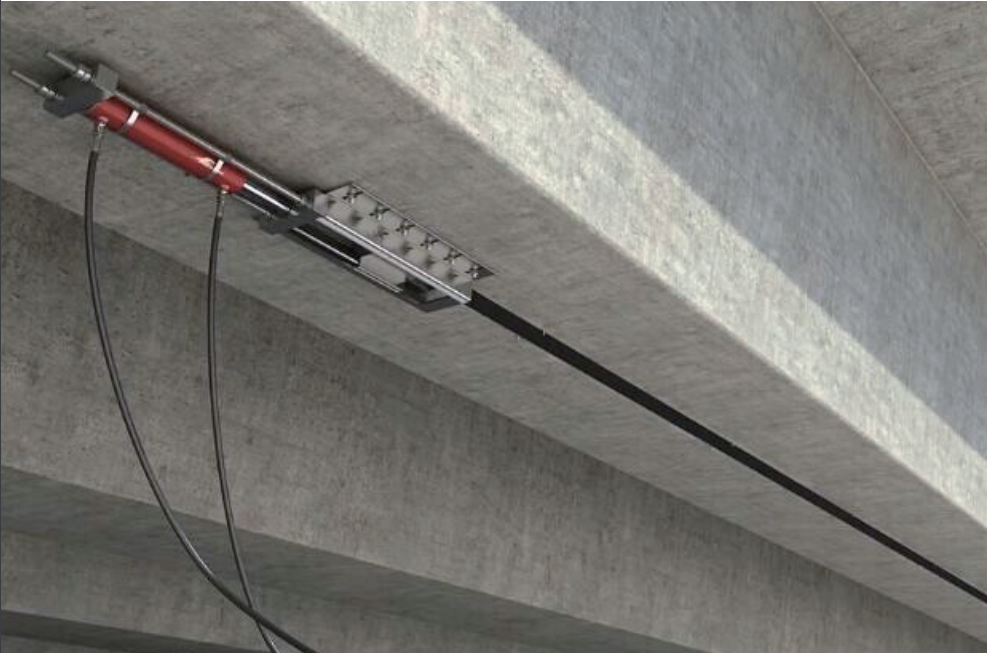

Figure 1 is the construction site diagram of the prestressed carbon fiber strip reinforced concrete bridge. Traditional bridge reinforcement technology is relatively passive, and does not significantly improve the overall internal force of the structure, and it is difficult to give full play to the strength limit of supplementary materials. As a representative of the new reinforcement technology, the prestressed carbon fiber strip has the advantages of easy formation of bonded prestress and good corrosion resistance, which can improve the bearing capacity of the beam structure and effectively delay the yield of the steel bar. It not only makes up for the defects of traditional bridge reinforcement, but also has a good application prospect, which can promote the innovation, technology and science of bridge reinforcement.

First of all, according to the condition of the reinforced concrete bridge, the value range of the prestress degree, the detailed information of the prestressed carbon fiber strip, the layout design and the size design of the anchor system should be determined. Establish a finite element model, compare the bearing capacity of the bridge before and after reinforcement, and calculate the value range of the stress degree through the bending moment expression method. After determining the degree of prestress, the cross-sectional area of the required prestressed carbon fiber strip is calculated and the amount is derived, and the I-type carbon fiber strip is used. According to the layout of the designed tensioning tonnage, the width of the carbon fiber strip is selected, the 1.4mm carbon fiber strip is selected, and the unbonded carbon fiber strip is used for reinforcement. The tension control stress is taken as 0.6fpk, and the prestress loss is calculated according to the characteristics of the anchor system and the tensioning process.

Second, implement construction control technology. Prepare the bridge for construction and treat surface cracks. Install the anchor rod and anchoring device according to the design drawings, and install the anchor head on the cleaned carbon fiber strip for on-site cutting. The tensile force and elongation of the prestressed carbon fiber strip are monitored from two aspects of stress disturbance, and the clamping method of the carbon fiber strip is determined according to the monitoring results, and the tensile prestress is appropriately adjusted to ensure the quality of reinforcement construction.

Figure 2 shows the application of prestressed carbon fiber strip anchoring system in bridge reinforcement. The carbon fiber strip is made of high-quality carbon fiber raw materials and basic resin, which is a kind of carbon fiber reinforced plastic, which has the characteristics of tensile resistance, shock resistance, fatigue resistance, corrosion resistance and so on. With its high safety factor, high technical reliability index, light weight, and small space requirements, it has been widely used in bridge reinforcement.

The specific applications are as follows. First, construct the prestressed carbon fiber strip anchor system, using anchors (both ends), carbon fiber strips, ordinary steel bars, bonding glue, carbon fiber adhesive, tensioning devices and tensioning equipment as the main materials to form the prestressing force. Carbon fiber strip anchor system.

Secondly, in terms of construction points, process and technical points, according to the bridge disease design reinforcement plan and anchor block position, make carbon fiber anchors, determine the specifications of carbon fiber strip, and strengthen the position. After repairing the beam surface defects, positioning the anchoring area, perforating chemical anchor bolts, and planting bars, scrub the carbon fiber strip and apply adhesive glue. Finally, install the carbon fiber strip anchors on the solidified chemical anchor bolts and the tension area, install the jack to stretch the carbon fiber strip, and put the carbon fiber strip close to the concrete surface to strengthen the diseased bridge.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.