Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Some Knowledge You Need To Know About Carbon Fiber Reinforcement

Carbon fiber reinforcement is suitable for reinforced concrete structural members. The fiber composite material used for reinforcement is used as the reinforcement material to directly bear the load, and the adhesive acts as the base material in the reinforcement to fix the carbon fiber and transfer the load.

1 Classified according to the technical methods and means used in reinforcement

Enlarged section reinforcement method, encased steel reinforcement method, pre-stressed reinforcement method, reinforcement method of changing the structural force transmission method, crack pouring repair reinforcement method, bonded fiber reinforcement method, bonded steel reinforcement method, etc.

The stick-fiber reinforcement method refers to a direct reinforcement method that uses a stick-type adhesive to paste the fiber-reinforced composite material on the concrete surface of the original member to form an integral composite section to improve the bearing capacity and ductility. The fiber mainly includes reinforced plastic, glass fiber, aramid fiber, carbon fiber and so on. The advantages of the fiber-bonded reinforcement method are similar to those of the steel-bonded steel reinforcement method. The construction method is relatively simple and the application range is wider. At the same time, it has the characteristics of corrosion resistance, moisture resistance, increased structural weight, durability, and low maintenance costs. It is suitable for the reinforcement of concrete structures and general structural components with various stress properties. While maintaining the original structural state, it satisfies the owner's requirements for the effective use of space and appearance of the building. The disadvantage is that since the fiber material exhibits linear elastic properties until it is broken, and it is obviously brittle when broken, it should be avoided to use for reinforcement of concrete structural members with a strength lower than C20, and special fire protection treatment is required.

2 Force analysis

According to the specification, carbon fiber reinforcement is suitable for reinforced concrete under bending, axial compression, large eccentric compression and tension members. The application method is generally to paste carbon fiber on the surface of the tension zone, and the fiber direction is consistent with the tension direction. However, carbon fiber reinforcement is not suitable for plain concrete members, nor is it suitable for reinforcement of members whose longitudinally stressed steel reinforcement ratio is lower than the minimum reinforcement ratio stipulated by the current national standards. Judging from my actual engineering reinforcement experience, carbon fiber reinforcement cannot greatly improve the bearing capacity of the structure, and the bending and shear bearing capacity of the beam is directly improved. The shear bearing capacity of the column is also improved to a certain extent, but the column is compressed and bent. The increase in bearing capacity is not obvious. And the specification also clearly stipulates that after reinforced concrete structural members are strengthened, the increase in the flexural bearing capacity of the normal section should not exceed 40%. And it should be checked to calculate the shear bearing capacity of the normal section to avoid the shear failure of the member before the bending failure due to the increase of the bending bearing capacity. If the bearing capacity of structural members is much different, other reinforcement methods should be used. Therefore, in a comprehensive reinforcement project, several reinforcement methods are often used to reinforce different concrete structural members to achieve the best stress state.

3 Performance inspection of fiber and adhesive

Because the fiber composite material used for structural reinforcement directly bears the load as a reinforcement material, its quality will directly affect the safety effect of the reinforcement and the engineering cost of the reinforcement, and the carbon fiber contained in it is the fundamental measure of the quality of the fiber composite material.

Adhesives for load-bearing structures play a more important role as a base material in reinforcement, fixing carbon fibers and transferring loads. They are divided into A and B grades according to their basic performance, and can be selected for use according to different stress conditions. For important structures, overhanging components, and structural components that are subjected to dynamic action, A-grade glue should be used; for general structures, A or B-grade glue can be used. Adhesives for load-bearing must be tested for safety performance. During the test, the standard value of the bond shear strength should meet the requirements of confidence level c=0.90 and 95% guarantee rate.

4 Precautions for construction of carbon fiber reinforcement method

4.1 Preparation for construction: Before construction, the moisture content of the surface layer of the concrete member at the sticking position and the ambient temperature should be measured. If the surface moisture content is greater than 4% or the ambient temperature is less than 50°C, measures should be taken to reduce the surface moisture content of the component, and construction can only be carried out after reaching the requirements. Before construction, the reinforcement should be laid out and positioned according to the design drawings.

4.2 Surface treatment: Deteriorated parts such as peeling, looseness, honeycomb, corrosion, etc. should be removed from the surface of the reinforcement member, until the concrete structure layer is exposed, and the cracked and missing corners of the concrete structure member should be filled. Confirm that the flatness of the concrete surface reaches 5mm/m; Grind the surface into an arc shape (radius of curvature R=20mm), and finally use a powerful blower or vacuum cleaner to completely remove the surface dust and wipe it with acetone to keep it dry.

4.3 Cut the carbon fiber cloth according to the size required by the design (generally 100mm, 150mm, 200mm or wider in width), and the edge of the cut cloth should be straight and smooth, and there should be no uneven corners.

4.4 Configure the adhesive according to the process requirements provided by the product supplier. The adhesive must be evenly mixed and applied to the surface of the concrete structural member where it needs to be pasted, without sag, and the curing time of the adhesive should be mastered according to the product description.

4.5 Apply the cut carbon fiber cloth on the base layer coated with adhesive. The carbon fiber cloth should be pasted in the order of the design direction. Use a special roller and a scraper to roll on the surface of the carbon fiber cloth in the direction of the fiber for many times to completely squeeze out the air bubbles, so that the adhesive can fully penetrate the carbon fiber cloth. Do not damage the carbon fiber cloth during rolling, and make sure that the carbon fiber cloth is free from wrinkles and skew.

4.6 When pasting in multiple layers, repeat the above steps layer by layer. The next layer should be pasted immediately after the surface of the carbon fiber cloth is dry to the touch. If it exceeds 60 minutes, wait 12 hours before applying the adhesive to paste the next layer.

4.7 A strip of adhesive should be applied evenly on the surface of the last layer of carbon fiber cloth.

4.8 Surface protection treatment: apply fire-resistant paint to meet the requirements of fire resistance level, and the environmental temperature for long-term use of the structure should not be higher than 60°C.

4.9 Considering the long-term durability of the structural adhesive used in the carbon fiber reinforcement method, the additional measures of "nail shot + compressed steel sheet" should be adopted for the main stressed fiber sheets in the reinforcement.

4.10 When using carbon fiber reinforcement method to reinforce reinforced concrete structures, measures should be taken to remove or remove most of the live loads acting on the structure.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

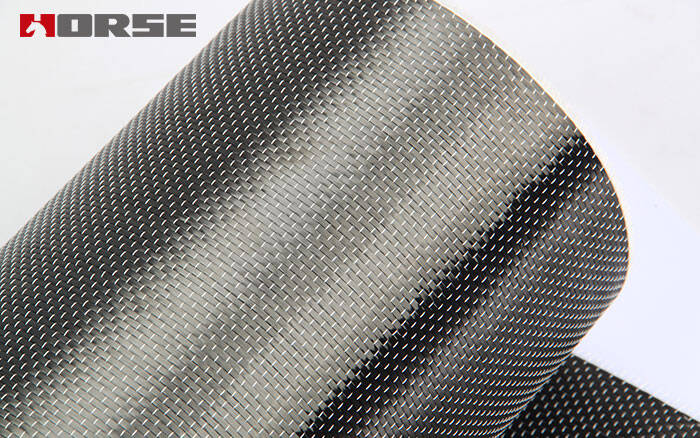

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.