Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Structural Reinforcement with Unidirectional Carbon Fiber

At present, new techniques have been developed used in the optimization of repair work, rehabilitation and structural reinforcement of buildings, techniques that come not only to revolutionize and improve the construction industry, but even better, to guarantee safety of the constructions.

Since the mid-80's a new reinforcement technique based on carbon fiber fabric and carbon fiber plates has been implemented which; As it is a material of very light weight, it is used as a reinforcement base to increase the structural resistance of the construction, but what is actually carbon fiber?

Structural reinforcement with unidirectional carbon fiber refers to the use of carbon fiber elements in a similar way to the steel bars of the structure; that is, complementing the longitudinal steel bars in the tensile areas, or the cutting stirrups, always bearing in mind that the carbon reinforcement capacity is unidirectional in the direction of the fibers, depending on the type of fiber being used. Carbon fiber known as Wrap are commonly used, whose arrangement is unidirectional but there are bidirectional configurations It is worth taking into account the fact that carbon fiber laminates have high mechanical characteristics that are much superior to those of concrete and steel. ,

The carbon fiber is a synthetic fiber composed of fine filaments of 5 to 10 microns in diameter and composed mainly carbon . Each carbon filament is the union of many thousands of carbon fibers. It is a synthetic fiber because it is manufactured from polyacrylonitrile . It has mechanical properties similar to steel and is as light as wood or plastic. Due to its hardness, it has greater resistance to impact than steel.

This type of unidirectional carbon fiber system allows to increase the capacity of reinforced structures since it is almost 10 times stronger than steel to reinforce concrete elements . It allows to reinforce structural elements due to deficiencies in the construction without demolishing, expanding sections, or delaying the work and its application is simpler than the traditional ones, since it does not imply invading so much space within the place that you want to reinforce, in addition to the fact that it is usually faster labor work than other applications.

Among the advantages offered by this type of material are:

Higher levels of resistance than other types of elements, such as steel and concrete.

High thermal insulation capacity.

Resistance to temperature variations.

Very light material.

Time saving in its application.

And it arises mainly when a telluric movement occurs, but also due to accidents (fire) and the use of the property, sometimes it goes from being a house room to being offices where there are changes in the furniture and the people who will be in the place, already Sometimes there are changes from simple offices to complete factories, where if the structure is not revised, there can be great damage to elements such as columns or slabs. This is because every building, house, factory, etc. It is designed to support a certain weight and if the use is changed it is likely that the furniture, machines or the number of people who will be occupying said property will increase.

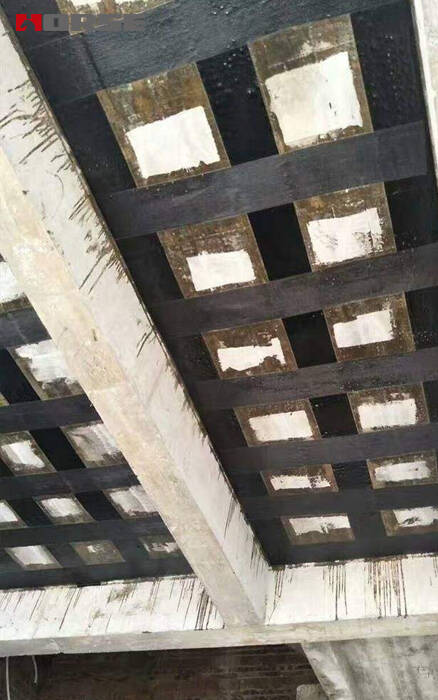

The places where unidirectional carbon fiber reinforcement can be applied are mainly in beams, in which it allows them to increase the resistance to bending and shear reinforcements, the design resistance and increase the stiffness of the beam, in columns where it adds greater rigidity and in slabs where its resistance and rigidity increases ...

Sheets are bonded to structures as external reinforcement using epoxy resin

The most common uses are:

Increased live load capacity in buildings and bridges, floors in hospitals, roof slabs in buildings, etc.

Seismic reinforcement of structural elements such as columns, unreinforced masonry walls, etc.

Repair of large diameter pipes to achieve reinforcement and permeability.

Repair of structural components damaged due to aggressive environmental conditions, fire, vehicle impact, aging, etc.

Changes in the structural system: new openings in the slab, demolition of existing walls, perforations, etc.

Design or construction error correction: wrongly placed reinforcing steel rods, insufficient superelevation, etc.

Advantages of unidirectional carbon fiber for structural reinforcement:

It is a strong and resistant fabric, ideal for confined spaces.

It is used for bending and shear reinforcement as well as for confinement.

Great modulus of elasticity.

Non corrosive.

Versatile; can be used to wrap complex shapes.

Light in weight; it does not alter the mass or dynamic loads on the structure.

Resistance to alkaline environments.

Thin in section, they can be easily crossed and overlapped.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.