Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber Structural Reinforcement - A Practical Method Of Masonry Strengthening

Among the building structure types, masonry structure buildings are an earlier architectural form. At present, there are still a large number of such buildings in China, and they are especially common in school buildings. Compared with reinforced concrete buildings, masonry structure buildings have poorer shear, tensile and flexural properties. In addition, it was built earlier, lacked the concept of seismic fortification, and did not pay enough attention to seismic fortification, and did not carry out special seismic design. There are also some problems in its structure.

For the reinforcement and strengthening of masonry structures, pasting carbon fiber composites has become more common in recent years. Its basic principle is to use a high-performance adhesive to paste the carbon fiber sheet on the surface of the masonry member to be reinforced, so that the two work together to give play to the high-strength performance of the carbon fiber sheet and improve the load-bearing capacity of the member.

Now, let's talk about the application of carbon fiber cloth in masonry structure.

1.Shear reinforcement of masonry

Pasting carbon fiber cloth can effectively improve the shear bearing capacity and seismic performance of masonry walls with openings and windows. This method is mainly suitable for in-plane shear reinforcement and seismic reinforcement of sintered ordinary brick walls. The use of carbon fiber cloth for reinforcement is also equipped with a special adhesive.

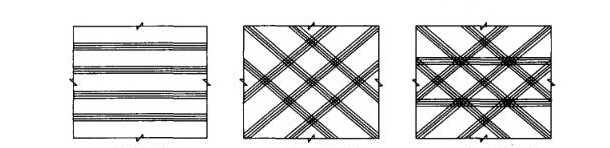

The reinforcement method of pasting carbon fiber composite material to improve the shear bearing capacity in the plane of the masonry wall can be selected according to the actual situation of the project: horizontal pasting, cross pasting, flat fork pasting or double fork pasting, etc. The ends of each method should be affixed with vertical or horizontal pressure strips.

unidirectional carbon fiber sheet for masonry

2. Seismic reinforcement of masonry

In the masonry structure house, the wall is the main load-bearing component. It not only bears the vertical load, but also bears the horizontal and vertical seismic action, and the force is complicated. Coupled with the brittle nature of the masonry itself, cracks are prone to occur on the wall during an earthquake. Under repeated earthquakes, the cracks will continue to develop, increase, and widen, eventually leading to the collapse of the walls, the collapse of the floor, and the destruction of the houses.

Earthquake-resistant reinforcement of masonry structure houses can improve their seismic load-bearing capacity by improving the stress-bearing method of the structure. According to the results of the seismic inspection and appraisal report of the structure, choose the overall reinforcement of the structure or the reinforcement of the local parts for different forms of damage, so as to be safe, effective, economical and reasonable, reduce the impact on the normal use of the building, and take into account the appearance of beauty.

The research results show that the effect of carbon fiber cloth on the reinforcement of masonry structures is very obvious, which greatly improves the seismic performance of masonry structures under horizontal action.

In terms of design, the calculation of the seismic and shear bearing capacity of the original masonry is the same as that specified in the current national standard "Code for Design of Masonry Structures" GB50003. The contribution of carbon fiber can be simply considered that its seismic shear capacity is the same as the non-seismic shear capacity. This treatment is biased towards safety.

In construction, when sticking carbon fiber cloth to strengthen the brick wall for seismic reinforcement, the direction of the fiber force should be designed to only bear the tensile stress. The fiber composite material pasted on the surface of the masonry should be protected. Generally, the floating dust and dirt on the surface of the component should be cleaned up first, and the component parts that need to be pasted with carbon fiber should be treated in advance, and smoothed. Continuous pasting should be used to enhance the overall performance of the wall.

3.Construction regulations of carbon fiber composite materials for masonry

3.1. Carbon fiber cloth strips should be evenly spaced on the entire wall. The strip width should not be less than 100mm. The large net spacing of the strips should not be greater than the height of the three-skin bricks, and should not be greater than 200mm.

3.2. There should be reliable anchoring measures along the direction of the carbon fiber cloth strips.

Set the tension structure along the direction of the carbon fiber cloth strip

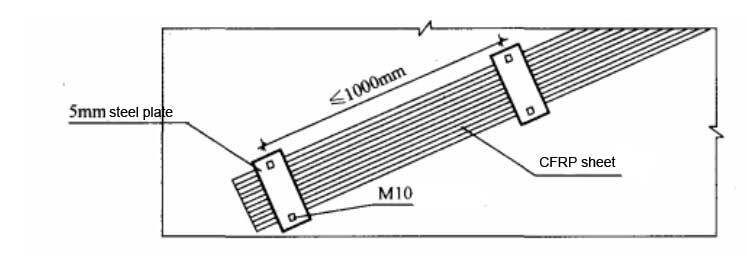

3.3. The anchoring structure measures at the ends of the carbon fiber cloth strips can be pressed firmly by butting bolt pads according to the conditions of the wall ends. When the carbon fiber cloth strip needs to go around the external corner, the radius of curvature at the corner of the external corner should not be less than 20mm. When there is reliable engineering experience or test data, other mechanical anchoring methods can also be used.

3.4. When the long carbon fiber cloth strip is connected by lap, the lap length should not be less than 200mm, and an anchor bolt should be set in the middle of the lap length.

3.5. When the brick wall is reinforced with carbon fiber composite materials, the surface of the walls and columns should be smoothed with cement mortar, and the layer thickness should not be less than 15mm and should be flat. The strength grade of cement mortar should not be lower than M10; the pasting of carbon fiber composite materials should be done after the smoothing layer is hardened and dried.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

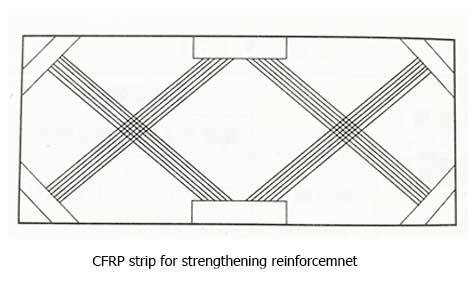

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.