Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber in the Reinforcement Engineering of Building Structure

Advantages of using carbon fiber reinforcement technology in building structure reinforcement projects

First of all, better corrosion resistance and waterproof performance.

Specifically, when dealing with the surface concrete structure, the use of epoxy resin with better waterproof properties can avoid water seepage, and then give effective protection to the surface building concrete structure. At the same time, carbon fiber materials can maintain long-term stable material properties, resist corrosive external factors, and fully extend the service life of the overall structure of the building. It can be seen that carbon fiber with good corrosion resistance and waterproof performance can objectively reflect the best building reinforcement effect"

Secondly, the cutting operation of carbon fiber materials can be carried out at will.

Compared with other hard reinforcement materials, the use of carbon fiber as a construction material has better construction convenience. This is mainly because the carbon fiber material itself has good flexibility and will not change the inherent external shape of the building structure. On this basis, free cutting operations can reflect the best adaptability of the building structure and save the cost of strengthening the structure of the building.

Third, it simplifies the construction operation process of building reinforcement.

At present, carbon fiber materials have been widely used in many building reinforcement fields, and have effectively replaced the traditional reinforcement materials of bending steel and shear steel. Carbon fiber with light and thin texture does not require too much pre-construction processing, so it can be directly processed by hand-cutting to ensure high reinforcement construction efficiency and simple reinforcement operation process. If carbon fiber materials can be used correctly for the reinforced building structure, the original structure appearance form can be retained without destroying the inherent building form. Table 1 compares carbon fiber with common structural reinforcement materials.

| Performance | Corrosion resistance | Water resistance | Tailorability |

| Ordinary building materials | Poor | General | Poor |

| Carbon fiber strengthening material | Good | Good | Good |

Analysis on the key points of reinforcement technology

Compared with other types of building reinforcement materials, carbon fiber materials can reflect better building reinforcement efficiency, and there is no need to rely on huge construction facilities for reinforcement. For example, when reinforcing pre-stressed building hollow slabs, if carbon fiber is selected to complete the corresponding reinforcement operation, the purpose of controlling reinforcement construction noise and simplifying the reinforcement operation method can be achieved, and effective cost savings in reinforcement treatment can be achieved. Specifically, in the practical operation of strengthening the building structure, the use of carbon fiber materials is mainly reflected in the following technical points

1 About the reinforcement of building compression members

If the concrete square column structure needs to be reinforced, then a uniform carbon fiber material should be wrapped around the square column. Through the use of the above winding treatment methods, the solidity and bearing capacity of the square column structure will be significantly enhanced. In addition, the treated concrete column will not easily break, which helps to optimize the bearing performance of the structural body. Specifically, when the compression member of the building body is reinforced, the concrete material will be subjected to lateral restraint force, which mainly comes from carbon fiber. Therefore, the lateral restraining force will prevent the continuous shape change of the main structure of the building and help maintain the solid and stable overall structure of the concrete.

For example, when necessary reinforcement is performed on important building parts of hollow core slabs, carbon fiber is usually used to achieve the purpose of reinforcement. When reinforcing various types of civil buildings, the use of carbon fiber can reflect good building crack resistance, earthquake resistance and corrosion resistance. In addition, the above carbon fiber materials can also be selected for reinforcing special structural parts. For example, for building walls that are prone to leakage, such as toilets, carbon fiber can usually be used for reinforcement.

2 On the reinforcement of building bending members

Generally speaking, the bending members of concrete buildings are arranged in the normal section of the building. Therefore, when strengthening concrete members with bending performance, the key is to maintain the stability of the front section of the building, and avoid the compression of external forces, which may lead to the distortion of the front section. After the reinforcement construction, the concrete structure of the front section can be inspected by means of strength testing. Compared with the reinforcement effect of other materials, the use of carbon fiber objectively reflects better cross-section stability and cross-section support strength, and can also achieve a significant effect of increasing the load force of the bending part.

At the same time, the flexural components of the building after reinforcement treatment will not easily appear cracks, and the inherent crack width inside the component can also be effectively shortened. Therefore, it can be confirmed that carbon fiber reinforcement is suitable for the flexural normal-section concrete members. This reinforcement method helps to maintain a uniform distribution of building cracks, and at the same time achieves the effect of significantly reducing the original crack width and the number of cracks. Specifically, in the process of strengthening the bending concrete members, the construction personnel should mainly ensure the correct combination of bonding materials. Furthermore, it reflects the best building reinforcement construction effect, and the light and thin carbon fiber should be given priority.

3 On the reinforcement of building shear members

In building structures made of concrete, shear members usually exist in inclined building structures. Specifically for this type of concrete components, necessary reinforcement treatments should be given to them at regular intervals to prevent the concrete components from losing good material shear resistance. Specifically, in the process of strengthening shear members, carbon fiber materials have been effectively used at present to ensure that the optimal amount of material reinforcement is limited. And follow the construction ideas adapted to local conditions to make a reasonable choice of anchoring methods. In this process, carbon fiber will reflect its unique flexibility advantages, avoiding deformation or bending of shear structural parts.

For example, for concrete shear structures, it is currently possible to apply necessary reinforcement operations by pasting U-shaped carbon fiber materials. In addition, the construction method of carbon fiber winding can be used to strengthen the inclined building section. However, it should not be overlooked that the use of carbon fiber winding may consume a long construction processing time and involve relatively complex reinforcement construction procedures. In comparison, the use of pasting carbon fiber can better reflect the good carbon fiber reinforcement effect.

Therefore, after analysis, it can be seen that carbon fiber can be used to reinforce various types of concrete members. Specifically, when carrying out all-round reinforcement construction operations, the basic premise is to combine the characteristics of the building itself to ensure the use of scientific methods to select multiple types of building reinforcement materials. Under the premise that carbon fiber is used as a construction material, the construction personnel need to thoroughly clean the surface of the building structure attachments, so as not to affect the effect of carbon fiber reinforcement operation.

Concluding remarks

After a long period of external erosion and aging of the building structure, the building components therein will slowly show a tendency to corrode, thereby affecting the overall safety of the building structure. Specifically, in the practical field of strengthening building structures, the use of carbon fiber as a new building reinforcement material can reflect better building reinforcement effects. Save the overall construction cost of building reinforcement, and achieve the goals of extending the life of the building structure and enhancing the stability of the building. In the current practice in the field of building structure reinforcement, the technical points of applying carbon fiber as a reinforcement structure material should be continuously summarized and summarized to ensure a good building structure reinforcement effect.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

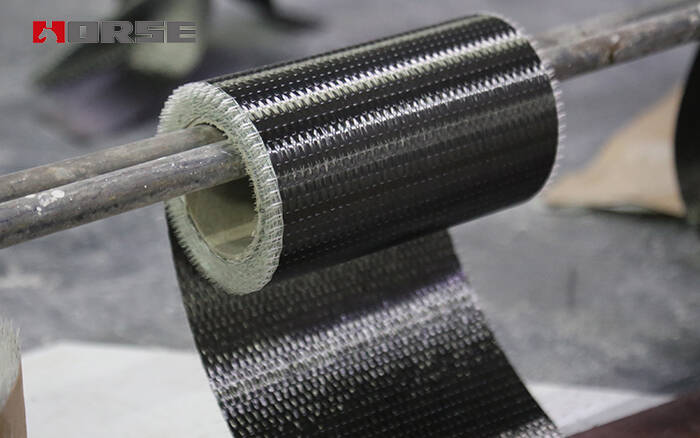

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.