Solutions

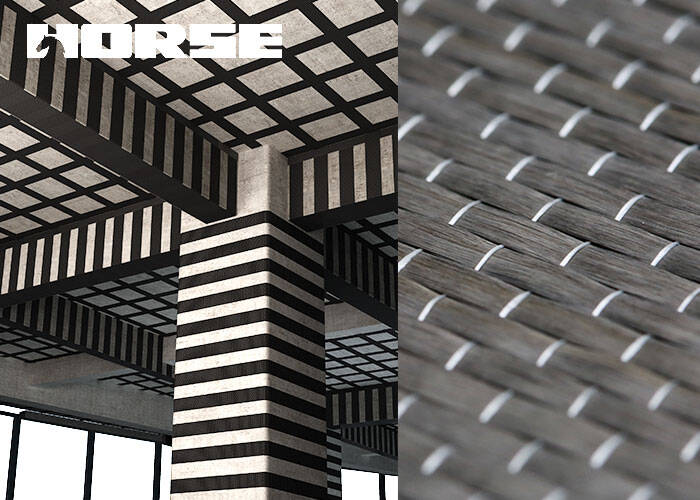

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Structrual Retrofitting And Repair Approximately 4 Billion Square Meters

About 4 billion square meters of structural retrofitting and repair needs are only part of old civil buildings. Most of my country's old industrial bases were formed in the 1950s and 1960s. More than 500,000 industrial projects of various types were built across the country, and the industrial building area was about 1.3 billion square meters that had been used for more than 30 years.

It is obvious that the reinforcement and repair of existing buildings will usher in peak demand! Reinforcement and retrofitting of building structure belong to the construction of existing building structure, that is, it may break the force balance of the original structure. Therefore, corresponding construction and monitoring standards are needed. It is necessary to understand in advance how to effectively avoid some misunderstandings in reinforcement and retrofitting projects!

Reinforcement and repair of existing buildings has the following reinforcement methods

1 Foundation reinforcement

1.1 Foundation reinforcement and grouting reinforcement

1.2 Expanding the base

1.3 Anchor rod static pressure pile

1.4 Root pile

1.5 Pit static pressure pile

1.6 Grouting reinforcement

1.7 Other foundation reinforcement methods

2 Reinforcement of concrete structures

2.1 Increase section method

Enlarged section reinforcement method has simple construction technology, strong adaptability, and mature design and construction experience. It is suitable for the reinforcement of concrete of beams, slabs, columns, walls and general structures. However, the wet work on site construction takes a long time, which will have a certain impact on production and life, and the headroom of the reinforced building will be reduced to a certain extent.

2.2 Replacement concrete method

The advantages of the replacement concrete reinforcement method are similar to the enlarged section method, and the clearance of the building will not be affected after the reinforcement, but it also has the disadvantage of long wet working time. It is suitable for the reinforcement of concrete load-bearing members such as beams and columns with low concrete strength or serious defects in the compression zone.

2.3 Outsourcing section steel method

Bonded outer profile steel reinforcement method is also called wet outer steel reinforcement method, which is reliable in force, simple in construction, and has a small on-site workload, but uses a large amount of steel and is not suitable for use in high temperature locations above 600C without protection . It is suitable for the reinforcement of concrete structures that do not allow to significantly increase the cross-sectional size of the original member, but require a substantial increase in the bearing capacity.

When using the outer profile steel method to reinforce reinforced concrete solid web columns or beams, the following requirements shall be met:

1) The external force borne by the steel frame and the original column strengthened by dry-clad steel shall be distributed according to the ratio of their respective section stiffness. The calculation and structure of the steel frame shall comply with the current "General Specification for Steel Structures", and its production and installation are allowed to be implemented in accordance with the current relevant structural reinforcement construction standards.

2) The bearing capacity and section rigidity of the bonded steel coated steel shall be determined based on the joint work of the entire section.

3) The unloading before reinforcement by the outer profile steel method shall meet the design requirements.

2.4 Sticking steel plate method

The steel plate is bonded to the surface of the concrete component with a high-performance epoxy adhesive, so that the steel plate and the concrete form a unified whole, and the good tensile strength of the steel plate is used to enhance the bearing capacity and rigidity of the component.

2.5 Prestress method

The prestressed reinforcement method can reduce the stress level of the reinforced component, not only makes the reinforcement effect good, but also greatly improves the overall bearing capacity of the structure, but the reinforcement has a certain effect on the appearance of the original structure. It is suitable for the reinforcement of large-span or heavy structures and the reinforcement of concrete members under high stress and high strain. However, it cannot be used in an environment with a temperature above 60°C, and it is not suitable for structures with large shrinkage and creep of concrete under the condition of no damage.

2.6 Pasting FRP composite material method

In addition to the similar advantages of sticking steel plates, the sticking fiber reinforced plastic(FRP) reinforcement method also has the advantages of corrosion resistance, moisture resistance, almost no increase in structural weight, durability, and low maintenance costs. However, special fire prevention treatment is required, which is suitable for concrete structural members and general structures with various stress properties.

2.7 Other three reinforcement methods

When reinforced concrete members are reinforced by the following methods, the bearing capacity calculation and structural design should be carried out in accordance with the provisions of the current national structural reinforcement design standards:

1) Prestressed carbon fiber plate reinforcement method;

2) Pre-tensioned steel wire rope mesh-polymer modified cement mortar surface reinforcement method;

3) Wire winding reinforcement method

3 Steel structure reinforcement

3.1 Increase section method

3.2 Sticking steel plate method

3.3 Outsourcing reinforced concrete method

3.4 The other four reinforcement methods

4 Reinforcement of masonry structure

4.1 The method of adding reinforced concrete surface course

4.2 Cement mortar surface course with reinforced mesh

4.3 The other four reinforcement methods

① Reinforce the structural system reinforcement method;

② Reinforcement method of filling concrete in steel tube members;

③ Prestressed reinforcement method of steel structure;

④ Reinforce the curtain wall.

5 Wood structure reinforcement

6 Structural anchoring technology

Several major misunderstandings in the reinforcement and repair of existing buildings

1. Misunderstandings in building structure reinforcement and repair

Because the reinforcement and reconstruction design did not do the overall experience calculation, the reinforced part of the building was too strong, and the unreinforced part was weak. The building as a whole could not work in coordination and did not meet the requirements of seismic bearing capacity. Therefore, it is recommended to do the overall calculation design for the reinforced and reconstructed buildings.

2. Misunderstandings in building structure reinforcement and repair

Regardless of the rigidity requirements, new damage will occur due to insufficient rigidity after reinforcement and transformation, especially for some structural changes. For example, the beam height is insufficient when the joist pulls out the column, and the continuous beam slab has become a simply supported beam slab when the partial beam slab is removed. It is very dangerous to remove it without considering the structural reinforcement.

3. Misunderstandings in building structure reinforcement and repair

For the design of the brick-concrete structure to be transformed into an inner frame, the practice of adding foundations and beams, slabs and columns first, and then removing the inner walls and various layers of slabs was not taken. Instead, the internal walls and slabs are first demolished in the construction, and the external walls are unstable. Even if temporary supports are added, their supports will affect the construction space and deform, which will cause unsafe factors in the reconstruction construction.

4. Misunderstandings in building structure reinforcement and repair

When the outer steel is used for reinforcement, the adhesive glue is used to paste the outer steel and then welded, which will cause the welding to burn out the adhesive glue, or the adhesive glue is not paid attention to, use unqualified glue, and replace the glue with cement mortar. Glue and so on.

5. Misunderstandings in building structure reinforcement and repair

It is believed that the role of adhesive glue without anchoring measures, or despite the addition of anchoring measures, the hidden dangers caused by factors such as low shear resistance and low bonding ability caused by the low strength of the reinforced concrete are still present. As a result, the bonding fails after the pasting and reinforcement, and the separation is chipped off, resulting in new hidden dangers or sudden failure of the structure during use.

6. Misunderstandings in building structure reinforcement and repair

Emphasizes the need to implement the provisions that should not be violated in the new construction code, so that it cannot be reinforced or allowed to freely, without scientific treatment measures, making the reinforced nodes and structures unreliable, etc., to two extremes.

Building reinforcement and retrofitting projects must have a professional construction team and the selection of high-quality reinforcement materials, otherwise it will lead to lax process control during construction, or process chaos, or no unloading measures, no monitoring behavior, etc. As a result, there are potential safety hazards during or after construction, unqualified inspections, and material performance requirements that cannot meet the corresponding specifications.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.