Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

56 Structural Reinforcement Techniques Methods For Bridges 2

56 Structural Reinforcement Techniques Methods For Bridges 1

https://www.horseen.com/index/solution/content/id/1003

5. Reinforced concrete and prestressed concrete continuous beam and cantilever beam bridge

Continuous beam bridges and cantilever beam bridges often have T-shaped, I-shaped and box-shaped sections. Most of the spans above 30 meters are box-shaped, and variable-height unequal-span beams are used. Continuous reinforced concrete beams of equal height generally have spans below 30 meters. Variable-height reinforced concrete continuous beams or cantilever beams generally have spans below 50 meters. Such bridges that use reinforced concrete materials with large spans require more materials and are prone to lateral cracks in the negative moment area of the bridge deck. Prestressed concrete continuous beams of equal height generally have a span of less than 60 meters. The prestressed concrete cantilever beams with variable heights are mostly under 100 meters in span, but over 100 meters are common. Most continuous beams have spans below 200 meters, but more than 200 meters are also common. This type of bridge is often used in crossing obstacles or urban overpasses, and various diseases are prone to appear regardless of the size of the span.

1) Reinforced concrete and prestressed concrete cantilever beam

(1) The deflection of the cantilever beam corbel end is too large, and the bridge deck on the top of the pier often cracks. Mainly caused by insufficient rigidity of the cantilever part, small size, the influence of overweight vehicles, or large longitudinal prestress loss and poor construction quality;

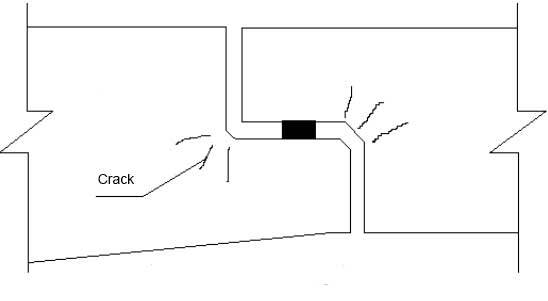

(2) Local cracks in the cantilever beam corbel, as shown in the figure below, are mainly caused by insufficient reinforcement, low height, temperature influence or poor connection between the suspension beam and the corbel, resulting in a jump, and excessive local impact;

(3) If the span of the anchor hole of the cantilever beam is too large, when the size is too small or the reinforcement is insufficient, it is likely that there will be mid-span deflection or vertical cracks at the bottom of the mid-span beam;

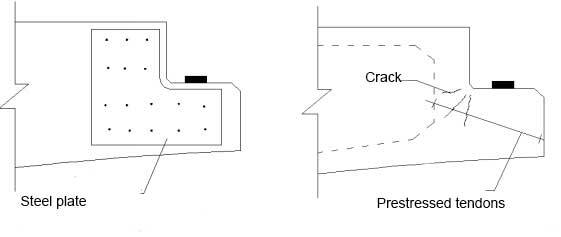

(4) Oblique cracks after the prestressed tendons are anchored to the tooth plate, which is a possible disease for all prestressed box girder, as shown in the figure below. It is mainly caused by excessive stress concentration near the tooth plate, less common steel bar configuration, and too concentrated anchorage of prestressed beams.

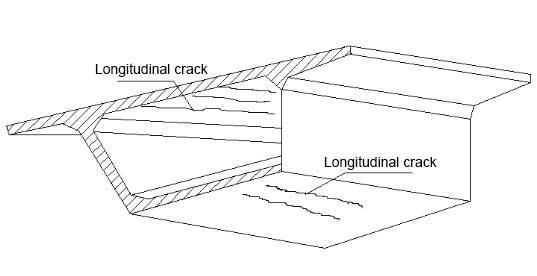

(5) Longitudinal cracks on the top and bottom of the box girder, as shown in the figure below. Mainly caused by excessively large transverse bending moments of the top and bottom plates, no transverse prestressing, space effect of transverse bending of box girder, small plate thickness, insufficient transverse reinforcement, and excessive temperature difference between the inside and outside of the box girder, resulting in temperature stress;

(6) Longitudinal cracks at the top and bottom of the box girder. The top and bottom axils are mainly because a large number of prestressed longitudinal steel strands pass through, and the local stress is too large. Either the positive shear lag effect of the box girder is not considered enough, or the distortion and torsion of the box girder under eccentric load causes excessive local stress on the lower end of the web;

(7) The vertical cracks in the middle of the box girder webs often occur within 2 to 3 days after demolding. They do not extend up and down. Most of them will be closed after prestressing. This is mainly caused by the shrinkage of concrete or the temperature difference between the inside and outside of the box girder or the horizontal reinforcement of the web. Insufficiency, or related to the quality of the concrete mixture;

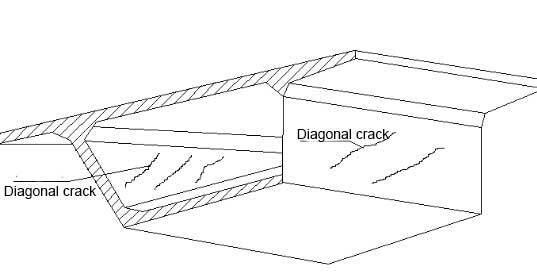

(8) Oblique cracks on the web of box girder, as shown in the figure below. Generally, it occurs on the beam section between the support point of the pier and the inverted point. It is a shear crack and the cause is more complicated. The main reasons are insufficient longitudinal or vertical prestress, or excessive loss, excessive temperature difference between the inside and outside of the box girder, insufficient bending or torsion rigidity of the box girder, excessive distortion stress of the box girder under eccentric load, small web thickness, and shear It is caused by the influence of force lag effect, insufficient configuration of non-prestressed steel bars, influence of concrete mixture and additives, improper construction, linear arrangement of longitudinal prestressing beams, and unreasonable span arrangement.

9) Horizontal cracks on the web of the box girder. It is mainly caused by the large vertical stress on the inside or outside of the web due to the space effect of the transverse bending of the box girder and the internal and external temperature difference stress, the insufficient transverse rigidity of the box girder, the influence of distortion stress, and the insufficient vertical prestress.

(10) During cantilever construction, cracks appear in the joints of each segment or the joints of the closed sections, which are often weak sections due to poor handling of the construction joints. Cracking under the action of longitudinal bending moment, concrete shrinkage or large temperature difference stress, or because the prefabricated joints are not dense, after the bridge deck cracks, the joints see water and the steel bars are corroded.

(11) When the box girder is wide, vertical cracks are likely to occur in the transverse partition or the transverse beam. This is mainly caused by insufficient or excessive loss of transverse prestress applied to the diaphragm or beam, or poor torsion resistance of the box beam.

2) Reinforced concrete and prestressed concrete continuous beam

Excessive mid-span downward deflection is often accompanied by lateral cracks at the bottom of the mid-span beam, cracks on the bridge deck at the top of the pier, or diagonal cracks in the web, mainly due to insufficient bending rigidity. Such as low beam height, thin web, insufficient longitudinal prestress or excessive loss.

Other diseases are the same as those of reinforced concrete and prestressed concrete cantilever beams.

The optional reinforcement methods for the above-mentioned diseases are:

(1) For the excessive downward deflection of the cantilever corbel end, the most effective method is to add prestress. Taking advantage of the characteristics of variable height beams, a full-length unbonded prestressed cable is arranged in the pavement layer and anchored to the corbel. A large number of anchor bars should be implanted between the pavement layer and the top plate of the box girder to transfer the bridge deck prestress. When the cross-section of a single box with multiple chambers is sufficient and the box height is sufficient, a full-length external beam can be arranged on both sides of the top of the middle web and anchored on the web, but attention should be paid to the impact on the anchoring holes.

(2) For cracks in the corbel, block steel plates or steel strips are often pasted on both sides, as shown in the figure. If the corbel in the box can be operated by people, consider drilling an oblique hole from the outside and then passing through the prestressed tendons to tension and anchor, as shown in the figure;

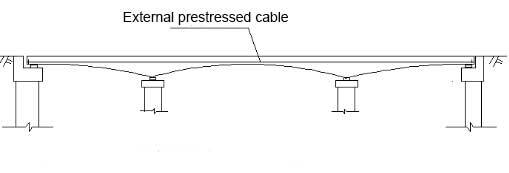

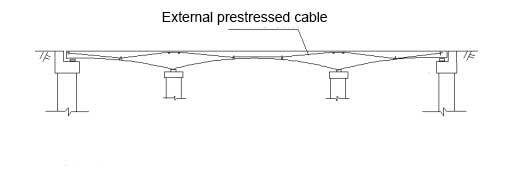

(3) For the continuous beam mid-span and the cantilever beam anchor hole mid-span deflection is too large, the most effective method is external prestress reinforcement. Taking advantage of the characteristics of variable-height beams, linear or broken-line external pre-stressed beams are arranged on both sides of the box inner web for reinforcement, and continuous beams of equal height should be reinforced with broken-line cloth beams.

(4) The cracks near the prestressed anchoring tooth plates are generally reinforced with composite materials such as thin steel plates or carbon fibers after filling the joints;

(5) For the transverse cracks on the bridge deck at the top of the pier, the concrete of the pavement layer can be cut out, and ordinary tensile steel bars or unbonded prestressed tendons shall be added on the roof surface, and the prestressed steel strands shall be anchored in the cast-in-place layer. Or set up external prestressed cable reinforcement above the cross-section center of gravity axis on both sides of the web in the box.

(6) For the transverse cracks at the bottom of the continuous beam, or the transverse cracks at the segmented joints, composite materials such as longitudinally pasted steel plates or carbon fibers are often used for reinforcement. Or use external prestressed cables for reinforcement. For the cracks in the segmented joints, if they are caused by non-stress, they only need to be sealed with glue;

(7) For the longitudinal cracks on the top and bottom of the box girder, methods such as pasting steel plates or other fiber composite materials transversely or adding transverse connections are often used to strengthen them. If the bottom surface of the top slab cracks longitudinally, it is mainly caused by the excessively large horizontal span of the top slab and no transverse prestressing is provided. Consider adding transverse prestressing tendons in the paving layer above the top slab. As shown in the figure below, a large number of anchor bars are implanted between the pavement and the roof to transfer the prestress of the bridge deck;

(8) The longitudinal cracks at the top and bottom of the box beam and the vertical cracks of the web can be reinforced by sealing, grouting or pasting fiber composite materials;

(9) For oblique cracks on the web, a steel plate or fiber composite material can be pasted on the web, similar to the following figure. Or increase the thickness of the web appropriately, or apply pre-stress longitudinally or vertically to strengthen it;

(10) For horizontal cracks on the web, vertical steel plates or fiber composite materials can be pasted on the web, or horizontal connections can be added, such as the addition of transverse partitions, or vertical prestress reinforcement;

(11) For the vertical cracking of the transverse partition or the cross beam in the box girder, the transverse external prestress can be added on both sides of the transverse partition and anchored through the box wall, as shown in the figure below. Or add transverse partitions to enhance the ability to resist transverse bending and torsion.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete